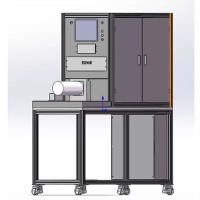

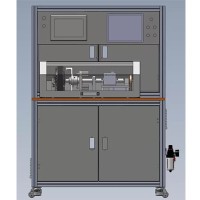

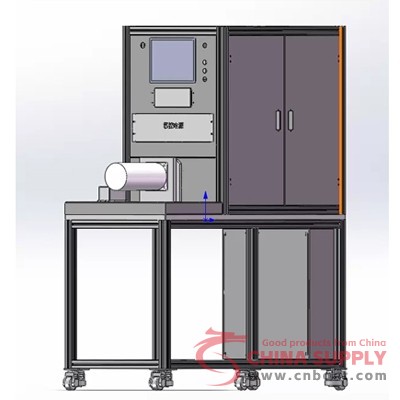

System Introduction:

The DC motor testing system is mainly used for rapid testing of the overall performance of DC reduction motor production lines. This testing system can achieve factory inspection of insulation withstand voltage testing, idle testing, load testing, locked rotor testing, and other testing items for the entire motor. The system has functions such as scanning codes, laser marking, remote data detection, and exporting test data. System testing fixtures are customized and developed according to customer samples, and can be quickly clamped; The device operation adopts one click operation, which has the advantages of high testing efficiency and quick user experience. The testing system adopts a touch screen+PLC solution, which has high system stability and simple graphics. The system is equipped with multiple data transmission interfaces, which can achieve automatic laser marking of qualified products, remote data upload, test data USB export and other extended functions, making it convenient for users to manage product quality.

Product Features:

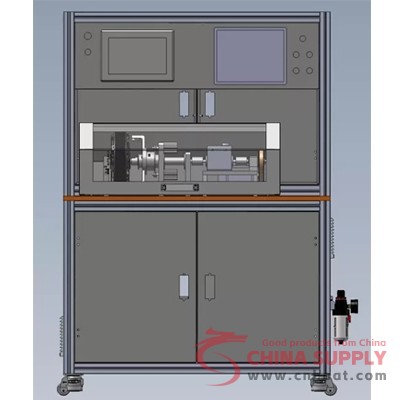

*Customize testing fixtures with automatic clamping fixtures based on the actual product of the customer, with a high degree of automation and one click operation to test all data.

*Optional scanning function, achieving one-to-one correspondence between test data and product numbers, and traceable management of product quality.

*The motor is powered by a programmable power supply, with a working voltage of 0-30V that can be set arbitrarily and a current of 0-10A that can be set arbitrarily.

*Adopting AC servo motor load, the load adjustment range is wide from 0-2NM and can be set arbitrarily; The load adjustment accuracy is high, and the minimum adjustment amount can reach 0.01NM.

*Equipped with motor voltage compensation function, the measurement data is more accurate and stable.

*Users can set upper and lower limits for various detection data, and if the data exceeds the limit, it will prompt "unqualified"; And sound and light alarm.

*Automatic saving of qualified product data during testing; Support USB data export for data archiving or product quality management.

*Laser marking system, testing qualified products, the system can print motor shell labels according to user designed labels.