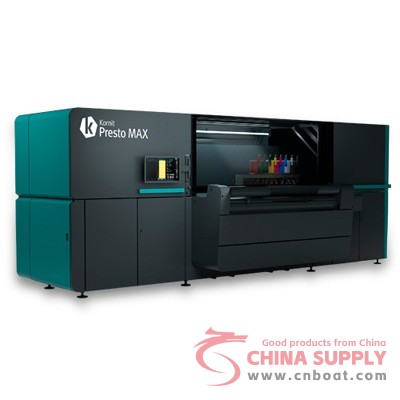

The most advanced one-stop direct spray fabric production increase solution

It also features a unique 3D body effect that imitates embroidery

There is no need to carry out any external process steps. From printing preparation to the finished fabric after printing, it only takes a few minutes to achieve the best results.

Product Introduction:

| Maximum output | 270 square meters per hour |

| Applicable materials | polyester, cotton, linen, polyester blend, etc |

| Ink color | 6-color CMYKRG + white + curing agent |

| Maximum width | 180 cm |

| Printing accuracy | 1000 dpi |

| Fabric feeding system | axial unwinding system, with adjustable fabric width and tension mechanism |

| Cloth conveying | High-precision belt conveying system |

| Ink type | NeoPigmenttm Robusto Water-based coating + Curing Agent (FOF) |

| Ink container | Supports 4 liters of ink |

| Ink circulation system | Built-in |

| Humidification system | built-in |

| Drying system | Modular integrated drying system |

| Equipment weight | 4500 kilograms |

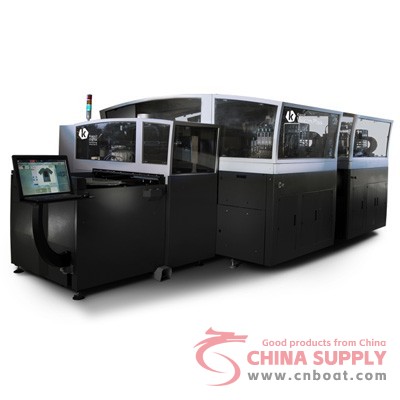

Kornit Advantage:

· No pre - or post-printing processes or chemical treatment procedures are required.

· It features a unique 3D cube-like tactile printing effect with embroidery.

· Zero water consumption, no pollution, green and environmentally friendly water-based ink.

· One type of ink enables printing on various fabrics and different fabric textures.

· It offers a wider color gamut to achieve highly realistic reproduction of printing.

· Customized printed product production is provided on demand, with no minimum order quantity limit.

· It only takes a few minutes from the printed draft to the finished fabric after printing.

· An outstanding combination of paint and ink creates vivid and long-lasting patterns

· Reserve a channel for adding fluorescent color print heads