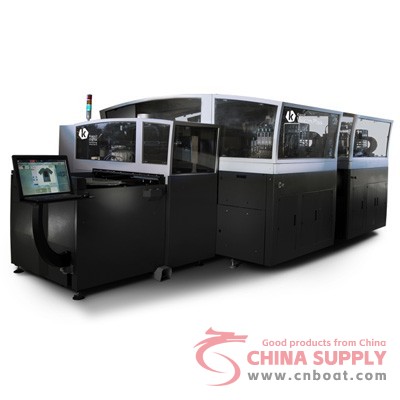

The most advanced one-stop direct spray solution for fabric (Presto for increased production)

There is no need to carry out any external process steps. From printing preparation to the finished fabric after printing, it only takes a few minutes to achieve the best results.

Product Introduction:

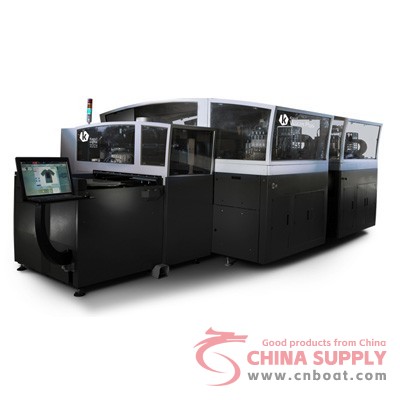

| Maximum output | 500 square meters per hour |

| Applicable materials | polyester, cotton, linen, polyester blend, etc |

| Ink color | 6-color CMYKRG + white + curing agent + softener |

| Maximum width | 180 cm |

| Printing accuracy | 1000 dpi |

| Fabric feeding system | axial unwinding system, with adjustable fabric width and tension mechanism |

| Cloth conveying | High-precision belt conveying system |

| Ink type | NeoPigmenttm Robusto Water-based coating + Curing Agent (FOF) |

| Ink container | Supports 4 liters of ink |

| Ink circulation system | Built-in |

| Humidification system | built-in |

| Drying system | Modular integrated drying system |

| Equipment weight | 4,500 kgs |

Process flow:

Printing truly realizes one-stop printing processes for polyester, cotton and other materials

Kornit Advantage:

· No pre - or post-printing processes or chemical treatment procedures are required

· Significantly increased production capacity compared to Presto.

· Zero water consumption, no pollution, green and environmentally friendly water-based ink.

· One type of ink enables printing on various fabrics and different fabric textures.

· It offers a wider color gamut to achieve highly realistic reproduction of printing.

· Customized printed product production is provided on demand, with no minimum order quantity limit.

· It only takes a few minutes from the printed draft to the finished fabric after printing.

· An outstanding combination of paint and ink creates vivid and long-lasting patterns