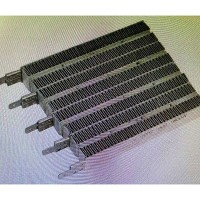

Air duct explosion-proof electric heaters are mainly used for heating air in air ducts, with three specifications: low temperature, medium temperature, and high temperature. The junction box is equipped with an over temperature control device. In addition to installing over temperature protection in the control aspect, a connecting device is also installed between the fan and the heater to ensure that a differential pressure device is added before and after the electric heater starts after the fan starts to prevent wind failure. The gas pressure heated by the channel heater should generally not exceed 0.3Kg/cm2. If it is necessary to exceed the above pressure, a circulating electric heater should be selected; The maximum temperature for gas heating in low-temperature heaters shall not exceed 160 ℃; Medium temperature type not exceeding 260 ℃; High temperature type not exceeding 500 ℃.

Features

01. It can heat the air to a very high temperature, up to 450 ℃, while the shell temperature is only around 50 ℃.

02. High efficiency: up to 0.9 or above.

03. The heating and cooling rate block can reach 10 ℃/S, with fast and stable adjustment. It will not cause temperature control drift due to the phenomenon of controlled air temperature leading or lagging, making it very suitable for automatic control.

04. Good mechanical performance: Because its heating element is made of specially made alloy material, it has better mechanical performance and strength than any heating element under the impact of high-pressure air flow. This is more advantageous for systems and accessory tests that require long-term continuous air heating.

05. Durable and long-lasting, with strict adherence to usage regulations, the lifespan can reach more than ten years.

06. Clean air is beneficial for environmental protection.

07. We can provide design solutions and customize multiple types of air electric heaters according to the actual needs of users.